5

SAVAGE INSPECTION GAGES

What most collectors forget when looking at a Th-

ompson is that every dimension with it's full range of

tolerances, on every part, on every gun had to be

inspected to insure quality and interchangeability.

All dimensions were checked by hand. Remember

this is in the days without computer controlled in-

spections. To help in these inspections, gages were

made to help the repeatability and the speed of the

work. However, sadly most of the gages have been

destroyed or lost to time.

Over the past few years I have been fortunate to have

several people (Robert Keene, Damon Gulich, Jerry

Prasser and others) find and recognize the historical

value of several gages and roll dies.

Previously, in the TCN (issues 110 and 111) we

showed gages and roll dies. The gages pictured here

have a Savage Arms history and are believed to have

been used during the WWII period. Each gage is

numbered and identified as belonging to A.O. (Auto-

Ordnance). The numbering system tells what each

gage is to inspect and where during the manufactur-

ing process the inspection is to take place.

So enjoy the photos. The information is based on a lot

of research time, but I found it fascinating.

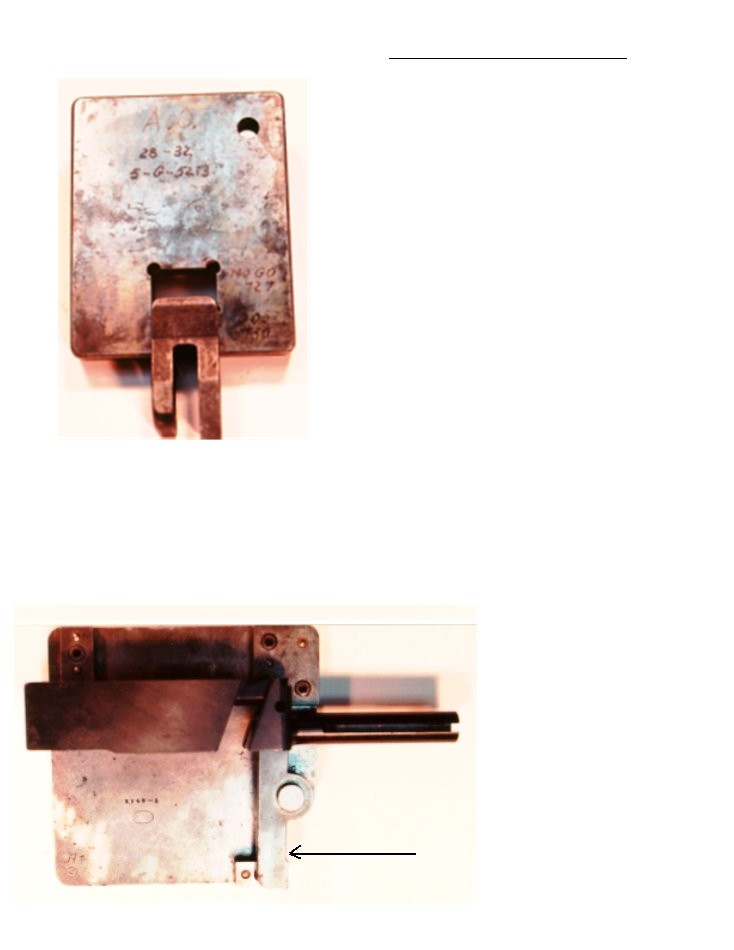

#28-32 NO GO/GO GAGE USED FOR

CHECKING THE WIDTH OF THE

SEAR ON THE LOW END OF ITS

TOLERANCE RANGE. IF THE PART

SLIDES ALL OF THE WAY INTO THE

GAGE IT WOULD FAIL.

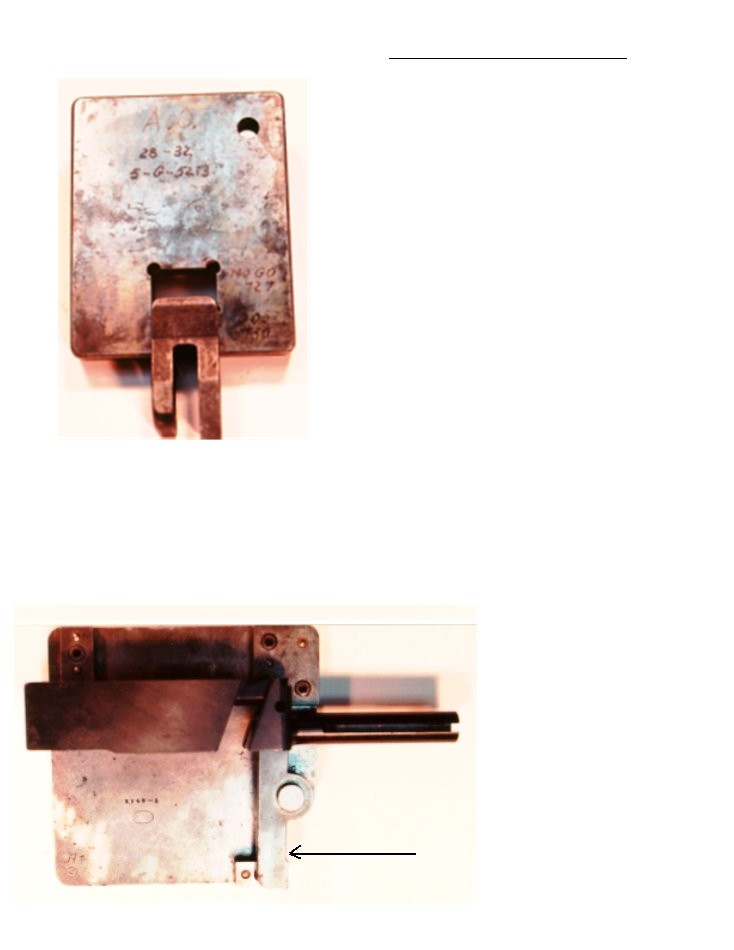

#3Y46-6 THE MASSIVE

PLATE CHECKS LOCATION

FOR THE HAMMER IN THE

BOLT. THE LEVER ON THE

RIGHT SIDE ROTATES TO

ACT AS AN EXAMPLE HAM-

MER.

ROTATING LEVER