4

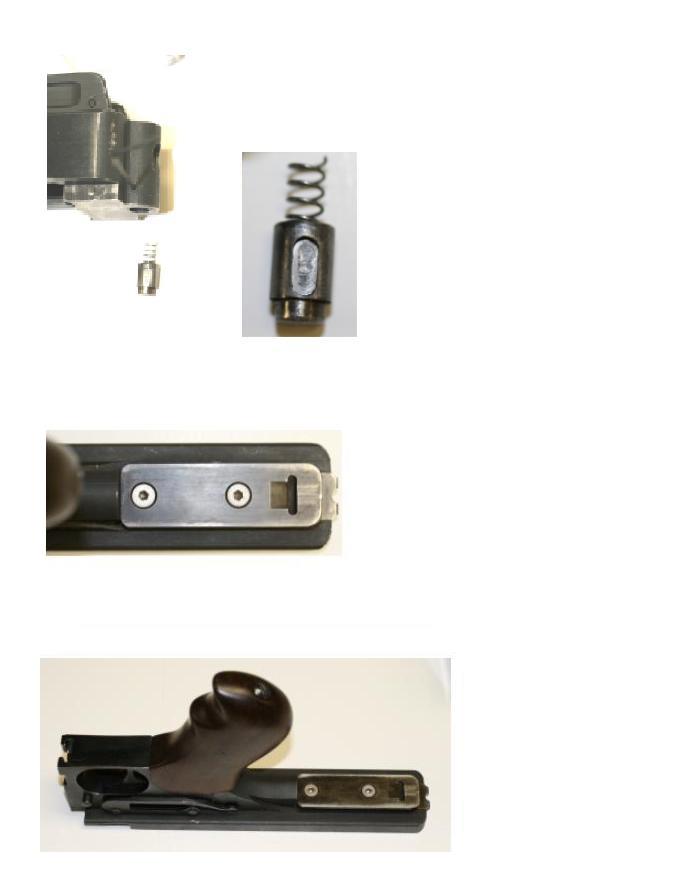

(Above) Rear of receiver with an Allen wrench inserted

into the set screw. (Above right) Close up of the frame

latch pin with the machined flat.

A previous owner had also enjoyed improving his

Model 1927A1. The first of these improvements was

to the spring loaded frame latch. On a full automatic

Thompson the latch is depressed and the frame and

receiver are separated. The latch is retained in the

depressed position by the frame and the frames in-

ternal parts. On the Model of 1927A1s, the frame

latch has to be held recessed by a screw driver to

allow the frame to clear it. This operation takes a

little bit of practice to get used to doing.

Serial number 153 has a small hole drilled and

tapped into the receivers frame latch hole recess.

Into this hole is inserted an Allen head set screw.

This set screw is then tightened down against a flat

that has been machined into the frame latch. When

tightened down the frame latch is held retracted or

extended. When retracted it makes taking apart the

receiver and frame much more user friendly.

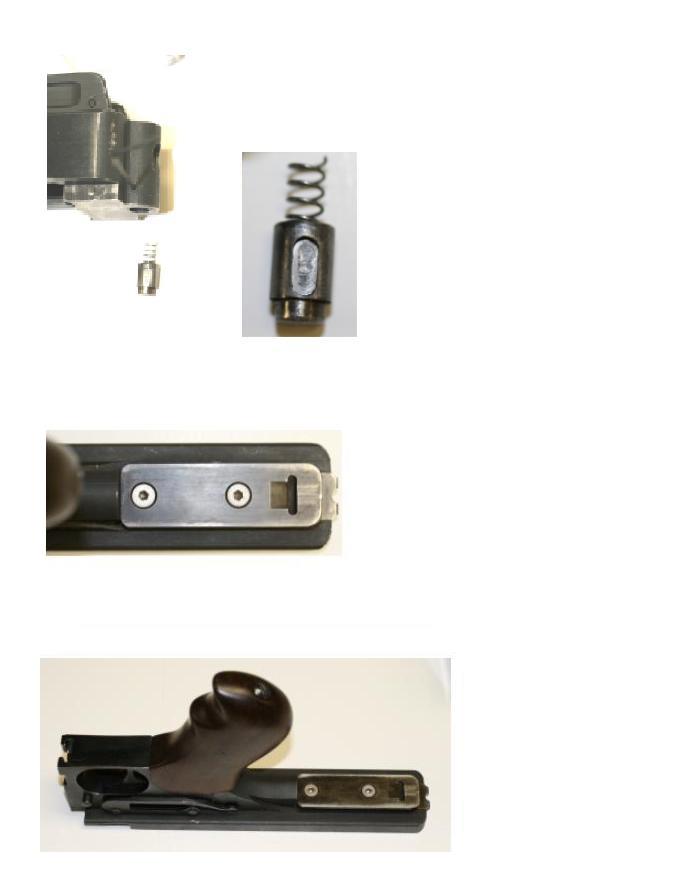

The second improvement feature was the installa-

tion of a removable buttstock mount on the trigger

frame. West Hurley sold a kit for this purpose.

The kit required the buyer to machine the trigger

frame to create a flat area for the mounting of a

bracket. The bracket was then screwed to the frame.

With the kit installed it would allow any World War

II or earlier M1928 buttstock to be used. However,

most buyers of the kits were unable to machine the

frames, due to expertise or lack of proper machines.

This one was installed very neatly.

West Hurley sold a kit for this purpose. The kit required

the buyer to machine the trigger frame to create a flat area

for the mounting of a bracket. The bracket was then

screwed to the frame.